www.engenharia-brasil.com

02

'09

Written on Modified on

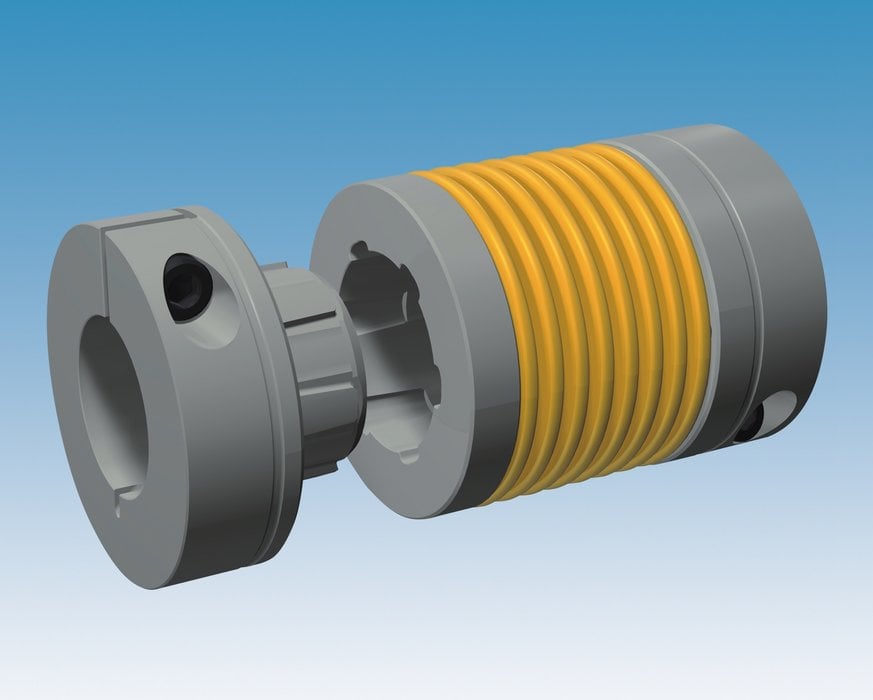

primeflex - A novo acoplamento de fole metálico topo de classe

primeflex representa uma tecnologia inovadora orientada para futuras aplicações a um preço excepcionalmente econômico. Em contraste com outros acoplamentos de fole, pode ser desmontada seguramente sem colocar a fole metálico em risco até mesmo depois de longo tempo de operação.

The MD-V covers the largest area without attenuating the laser accuracy. Marking in a large area often requires moving a target workpiece using an X-Y stage, or switching the lens on a conventional laser to create a wide marking area. Using an X-Y stage increases integration costs and time, and also decreases product throughput. A wide area lens can help these problems, however characters are often displaced or blurred at the edge of the marking area. The MD-V9900 Series utilizes a special lens system along with its unique 3-axis control to create a highly accurate 300 x 300-mm wide marking area, eliminating the need for mechanical adjustment while maintaining character integrity.

The MD-V9900 Series features also 3-Axis control to modify the laser position according to the shape of a target, which can include steps, inclined surfaces, cylinders or circular cones. The MD-V9900 Series minimizes distorted, worn, or chipped characters while enabling uniform marking on three-dimensional surfaces that are considered untouchable by conventional markers.

The MD-V utilizes an end-pumping YV04 laser system that generates an ideal laser beam. Conventional systems are forced to employ a multi-mode laser, leading to fluctuations in laser power and target quality. Single mode laser’s concentrate the beam to provide high quality marking on a wide range of surfaces.

Varying the spot size of the laser is helpful when trying to enhance the contrast of characters on specific materials, or engrave more deeply into the target surface. Typical defocus techniques may cause varying character size and position, while the MD-V can provide uniform quality of characters.

Smooth marking is possible on high speed production lines thanks to an ultra-high pulse recurrence frequency of 400 kHz. MD-V is particularly suited for pallet marking. Identical characters or serial numbers can easily be marked at high speed on multiple workpieces, such as electronic components in a tray. The MD-V can disable marking or correct inclination for individual targets. Additionally, the dedicated communication algorithm significantly reduces coordinate adjustment via communication lines.

Along with a system to verify the output value of the laser, the MD-V9900 also employs an internal system to monitor and automatically adjust for power variations that may occur over the lifetime of the laser. This feature will help to ensure that each mark is made with the same quality and consistency, regardless of the operator or age of the marking head.

All kind of signs or pictures can be marked: from numerical value, alphabet, to DataMatrix (ECC200), logo (CAD) data BMP / JPEG / PNG / TIF. Character sizes ranges from 0.1 to 300 mm. New photographical marking function: Along with an improvement in the marking control capacity, a gradation sequence marking mode has been added to the photographical marking function. The image expression is dramatically improved compared to traditional binary image processing.

Available interfaces are: RS-232C/RS-422A/USB2.0 2