www.engenharia-brasil.com

30

'14

Written on Modified on

Robustos sistemas de acionamento mostram o seu lado mais doce

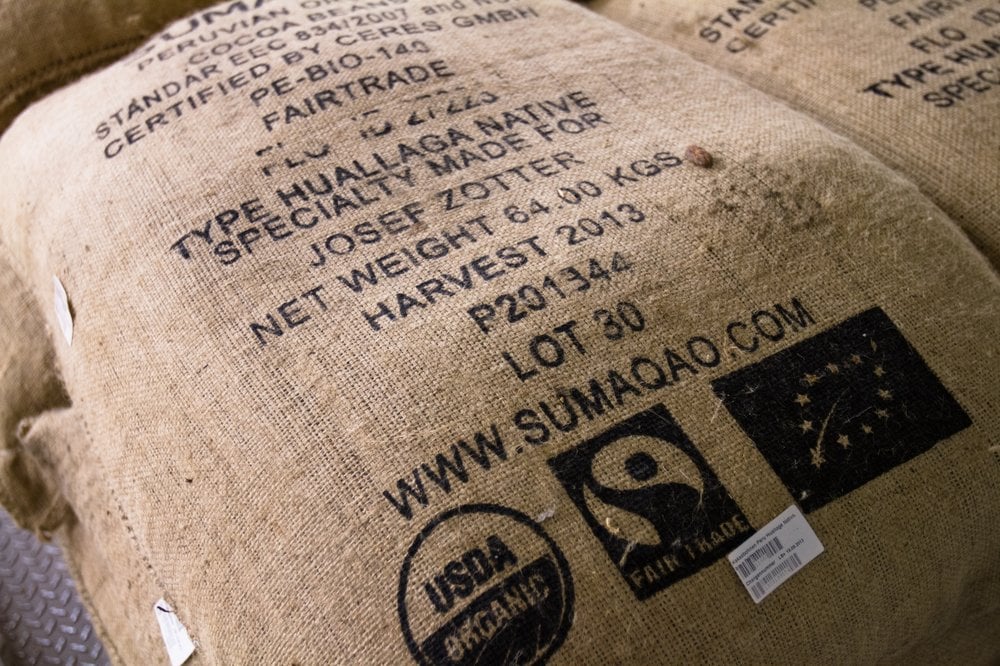

Muitos passos são necessários para fazer chocolate a partir de grãos de cacau. Ingredientes e misturas em vários estados devem permanecer em movimento quase que continuamente por horas e dias a fio. Esses processos requerem sistemas de acionamento de confiança. Na fábrica da Zotter Schokoladen, no sul da Áustria, a durabilidade e a operação segura dessas unidades é duplamente significativa. Em primeiro lugar, o bom funcionamento assegura a qualidade superior do produto final. Além disso, os visita fábrica é aberta a visitação todos os dias e os visitantes não devem ver nenhum tipo de problema.Durante anos, a Zotter utiliza os motoredutores da NORD DRIVESYSTEMS para as operações de transporte, mistura e bombeamento.

To improve its energy efficiency, CIAT's teams leveraged the standard version of POWERCIAT2, optimised the heat transfer area of its coils and evaporator, and added the latest generation of very low energy screw compressors. The result is a unit with an improved ratio of cooling capacity to power input that gives it a particularly high level of energy efficiency.

In addition to its low power consumption, POWERCIAT2 HEE features the same innovations and performance levels as the standard version, offering the best ratio of power to refrigerant charge on the market (7 kW of cooling/kg of R134a). POWERCIAT2 HEE is currently the only water chiller that combines both micro-channel coil and shell-and-tube dry expansion evaporator technologies. It has been engineered using eco-design principles to minimise its environmental impact throughout its entire life cycle.

Compared to the previous generation of water chillers, the major technical innovation of POWERCIAT2 HEE is its all-aluminium micro-channel coil and the many advantages this offers: 45% less refrigerant, 20% lighter machines (making them easier to handle, transport and install on site) and a 20% smaller footprint. It is also easy to maintain. The coil's rigid external surface is compatible with high-pressure cleaning and its all-aluminium design eliminates galvanic currents between different metals and offers greater resistance to corrosion.

POWERCIAT2 HEE also features COREVA2, a new shell-and-tube dry-expansion evaporator for which two patents have been filed. COREVA2's exceptional performance levels offer maximum output, reduced refrigerant charges and optimised pressure drops that enable it to achieve high energy efficiency. This technology is perfectly suited to new environmental constraints and the most stringent European standards.

POWERCIAT2 HEE is available with three noise levels: Standard, Low Noise and Xtra Low Noise. The Xtra Low Noise version has a sound pressure level of 63 dB(A) at 10 metres for just 1160 kW. This remarkable level is achieved thanks to a reduction in noise levels on each component. The latest-generation silent fans automatically adjust the flow of air to cooling requirements, the compressors are fitted on anti-vibration mounts and housed inside acoustically insulated boxes, and the intake pipes are equipped with flexible couplings that prevent the transmission of vibrations.

POWERCIAT2 HEE's partial recovery option uses waste heat to produce free hot water at temperatures of up to 60°C and meet domestic hot water needs in establishments such as hotels.

POWERCIAT2 HEE's exceptional performance levels make it the central element of the Hysys® POWER system that provides heating, cooling and indoor air quality for buildings in the tertiary sector. For large-scale projects, this optimised system can integrate a CIAT Energy Pool, the most advanced solution to the environmentally-responsible constraints linked to energy production.